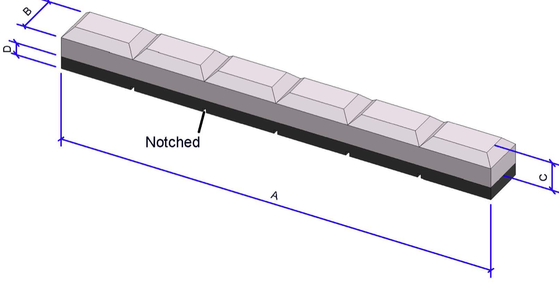

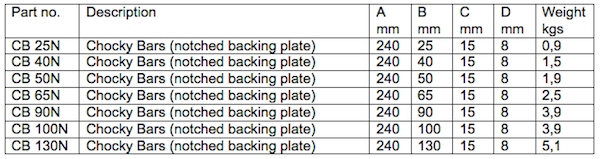

Wegusta Chocky Bars 725 HB / 63 HRC

WEGUSTA LAMINATED 725 HB / 63 HRC CHOCKY BARS ARE EASY TO USE

Chocky Bars are available in a wide range of sizes to fit all of your unique applications and are an inexpensive, effective protection alternative to expensive, labour intensive, hard facing welding or cutting methods.

Easy to install, cut and shape over contoured surfaces. There is also no pre-heating or post heating required when welding Chocky Bars into place.

Applications for Chocky Bars are broad and varied, ranging from wear protection on buckets for loaders, excavators, draglines machines, pump housings, impellors, chute/hopper linings to hammer tips for recycling industry.

If you contact us about the use of Chocky Bars for your particular applications, chances are high someone is already using it successfully for a similar application.

FEATURES OF CHOCKY BARS:

- metallurgically bonded martensitic white iron bonded to a weldable, impact resistant backing plate;

- 725 HB Chocky Bars offering superior wear and impact resistance when compared to Chrome-carbide clad plate and hard facing;

- Chocky Bars are manufactured with notch on the mild steel backing plate to be easily cut and shaped to fit over contoured surfaces.

BENEFITS

- ease of use and installation, can be formed in bends and curved surfaces;

- significant increase in lifespan when compared to AR plates, Chrome-carbide plates and hard facing;

- less downtime and maintenance on worn parts;

- very cost effective due to extended lifespan compared to hard facing and overlays.

APPLICATIONS OF CHOCKY BARS

- bucket wear strips;

- replaces hard facing for augers, directional drill heads, foundation drilling, raise bore drilling;

- fan blade liners;

- pugmill paddles, tip and scrapers;

- recycling industry;

- road planer skids and pick protectors;

- replaces hard facing for pump housings and impellors.

Wegusta Holland has its own warehouse facilities in The Netherlands from where we can supply the standard products out of stock. Also the special customised dimensions can be delivered in a short time.

| Cutting details | |

|---|---|

| Forming procedures |

|

| Welding procedures |